Table of Contents

Top LX Electric Crane Manufacturers in China

When it comes to electric cranes, LX Electric Crane (Electric Hoist) is one of the top manufacturers in China. With a reputation for high-quality products and reliable performance, LX Electric Crane has become a trusted name in the industry. In this article, we will take a closer look at LX Electric Crane and why they are considered one of the best factories in China for electric cranes.

LX Electric Crane is known for its commitment to quality and innovation. The company invests heavily in research and development to ensure that their products are at the cutting edge of technology. This dedication to excellence has earned LX Electric Crane a reputation for producing some of the most reliable and efficient electric cranes on the market.

One of the key factors that sets LX Electric Crane apart from other manufacturers is their attention to detail. Every crane that leaves their factory undergoes rigorous testing to ensure that it meets the highest standards of quality and performance. This commitment to excellence has helped LX Electric Crane build a loyal customer base who trust in the reliability of their products.

In addition to their focus on quality, LX Electric Crane also offers a wide range of products to meet the needs of their customers. Whether you are looking for a small electric hoist for light-duty lifting or a heavy-duty crane for industrial applications, LX Electric Crane has a solution for you. Their diverse product line ensures that they can meet the needs of customers in a variety of industries.

Another reason why LX Electric Crane is considered one of the best factories in China for electric cranes is their commitment to customer service. The company prides itself on providing excellent support to their customers, from the initial consultation to after-sales service. This dedication to customer satisfaction has helped LX Electric Crane build long-lasting relationships with their clients.

In addition to their focus on quality and customer service, LX Electric Crane also stands out for their competitive pricing. Despite offering some of the best products on the market, LX Electric Crane is able to keep their prices competitive, making them an attractive option for businesses looking to invest in electric cranes.

Overall, LX Electric Crane is a top manufacturer in China for electric cranes due to their commitment to quality, innovation, customer service, and competitive pricing. If you are in the market for an electric crane, LX Electric Crane is definitely a factory worth considering. Their reputation for excellence and reliability make them a trusted choice for businesses in a variety of industries.

| Number | Commodity Name |

| 1 | QZ OVERHEAD CRANE WITH GRAB CAP.5-20T |

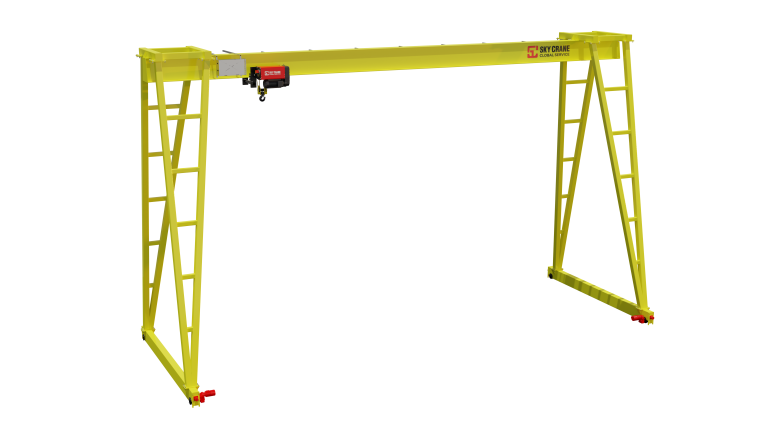

| 2 | Semi – gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In conclusion, LX Electric Crane is a leading manufacturer in China for electric cranes, known for their high-quality products, innovative technology, and exceptional customer service. With a diverse product line and competitive pricing, LX Electric Crane is a top choice for businesses looking to invest in reliable and efficient electric cranes.

Innovations in LX Electric Hoist Technology

The LX Electric Crane, commonly referred to as an electric hoist, has undergone significant advancements in technology, particularly within the leading factories in China. These innovations have not only enhanced the efficiency and safety of lifting operations but have also contributed to the overall sustainability of industrial practices. As industries continue to evolve, the demand for more sophisticated and reliable lifting solutions has prompted manufacturers to invest heavily in research and development, resulting in groundbreaking improvements in electric hoist technology.

One of the most notable innovations in LX electric hoists is the integration of smart technology. Modern electric hoists are now equipped with advanced sensors and control systems that allow for real-time monitoring of load conditions. This capability enables operators to receive immediate feedback on weight limits, ensuring that the hoist operates within safe parameters. Furthermore, these smart systems can detect potential malfunctions or irregularities, prompting timely maintenance and reducing the risk of accidents. By leveraging the Internet of Things (IoT), manufacturers have created electric hoists that can communicate with other machinery and systems, facilitating a more streamlined and efficient workflow in industrial settings.

In addition to smart technology, energy efficiency has become a focal point in the design of LX electric hoists. With growing concerns about environmental sustainability, manufacturers are increasingly prioritizing energy-saving features. For instance, many modern electric hoists utilize high-efficiency motors that consume less power while delivering superior performance. These motors are often paired with regenerative braking systems, which capture and reuse energy during operation, further minimizing energy consumption. As a result, industries can significantly reduce their carbon footprint while also lowering operational costs, making electric hoists a more attractive option for businesses committed to sustainability.

Moreover, advancements in materials science have played a crucial role in enhancing the durability and performance of LX electric hoists. The use of lightweight yet robust materials, such as high-strength alloys and composites, has led to the development of hoists that are not only easier to handle but also capable of lifting heavier loads. This innovation allows for greater versatility in various applications, from construction sites to manufacturing facilities. Additionally, improved corrosion-resistant coatings have been introduced, extending the lifespan of electric hoists and reducing maintenance requirements, which is particularly beneficial in harsh environments.

Safety features have also seen significant improvements in LX electric hoists. Enhanced braking systems, including dual braking mechanisms, provide an added layer of security, ensuring that loads remain stable even in the event of a power failure. Furthermore, many electric hoists now come equipped with overload protection systems that automatically halt operation when excessive weight is detected. These safety innovations are crucial in preventing accidents and ensuring the well-being of operators and personnel in the vicinity.

As the demand for efficient and reliable lifting solutions continues to grow, the LX electric hoist stands out as a prime example of how innovation can drive progress in industrial technology. The combination of smart technology, energy efficiency, advanced materials, and enhanced safety features positions these electric hoists as essential tools in modern manufacturing and construction. With Chinese factories leading the charge in these advancements, the future of electric hoist technology looks promising, paving the way for even more sophisticated solutions that will meet the evolving needs of industries worldwide. As these innovations continue to unfold, they will undoubtedly shape the landscape of lifting equipment, ensuring that businesses can operate more effectively and safely in an increasingly competitive environment.

Quality Standards of Chinese LX Electric Crane Factories

The quality standards of Chinese LX Electric Crane factories are pivotal in establishing the reputation and reliability of these essential lifting devices in various industries. As the demand for efficient and safe material handling solutions continues to rise globally, Chinese manufacturers have increasingly focused on adhering to stringent quality standards to ensure their products meet both domestic and international requirements. This commitment to quality is not only a response to market demands but also a reflection of the evolving landscape of manufacturing practices in China.

To begin with, many LX Electric Crane factories in China have adopted international quality management systems, such as ISO 9001. This certification signifies that a factory has implemented a comprehensive quality management system that encompasses all aspects of production, from design and development to manufacturing and customer service. By adhering to these standards, factories can systematically improve their processes, reduce waste, and enhance customer satisfaction. Consequently, this commitment to quality management has positioned Chinese manufacturers as competitive players in the global market.

Moreover, the integration of advanced technology in the production process has significantly contributed to the quality of LX Electric Cranes. Factories are increasingly utilizing automated machinery and robotics, which not only enhance precision but also minimize human error. This technological advancement allows for consistent product quality, as machines can perform repetitive tasks with a high degree of accuracy. Additionally, the use of computer-aided design (CAD) software enables engineers to create detailed models and simulations, ensuring that the cranes are designed to meet rigorous safety and performance standards.

In addition to technological advancements, the emphasis on material quality is another critical aspect of the manufacturing process. Reputable LX Electric Crane factories source high-grade materials, such as steel and aluminum, which are essential for the durability and strength of the cranes. By conducting thorough inspections and tests on raw materials, manufacturers can ensure that their products can withstand the rigors of heavy lifting and harsh working environments. This focus on material quality not only enhances the performance of the cranes but also extends their lifespan, providing customers with a reliable investment.

Furthermore, compliance with safety standards is paramount in the production of LX Electric Cranes. Factories are required to adhere to various safety regulations, such as those set forth by the Occupational Safety and Health Administration (OSHA) and the European Union\\u2019s CE marking. These regulations dictate the design, manufacturing, and testing processes to ensure that the cranes operate safely and efficiently. By prioritizing safety, manufacturers not only protect their workers but also instill confidence in their customers, who rely on these cranes for critical lifting operations.

In conclusion, the quality standards upheld by Chinese LX Electric Crane factories are a testament to their commitment to excellence in manufacturing. Through the implementation of international quality management systems, the adoption of advanced technology, the use of high-quality materials, and strict adherence to safety regulations, these factories have positioned themselves as leaders in the industry. As the global market continues to evolve, the focus on quality will remain a driving force behind the success of Chinese manufacturers, ensuring that they meet the ever-increasing demands for reliable and efficient electric cranes. Ultimately, this dedication to quality not only benefits the manufacturers but also enhances the overall safety and efficiency of operations across various sectors.