Table of Contents

Advantages of LX Electric Suspension Cranes in Industrial Applications

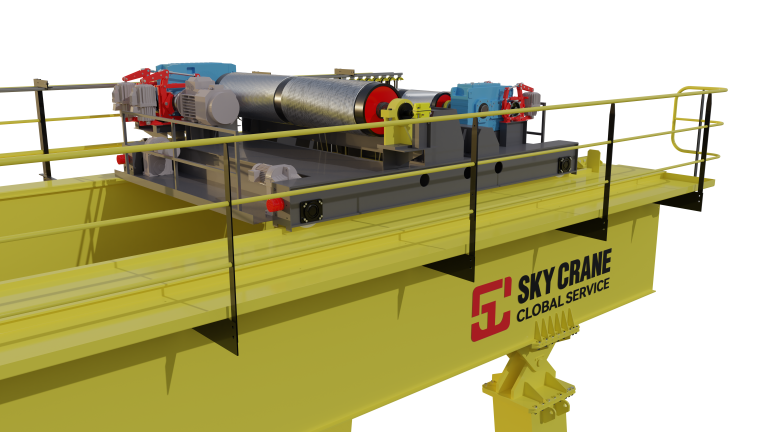

LX electric suspension cranes have emerged as a pivotal solution in various industrial applications, offering a multitude of advantages that enhance operational efficiency and safety. One of the primary benefits of these cranes is their ability to optimize space utilization in facilities with limited floor area. Unlike traditional cranes that require extensive ground support, LX electric suspension cranes are suspended from overhead tracks, allowing for unobstructed movement beneath them. This design not only maximizes the usable space but also facilitates the movement of materials and equipment without hindrance, thereby streamlining workflow processes.

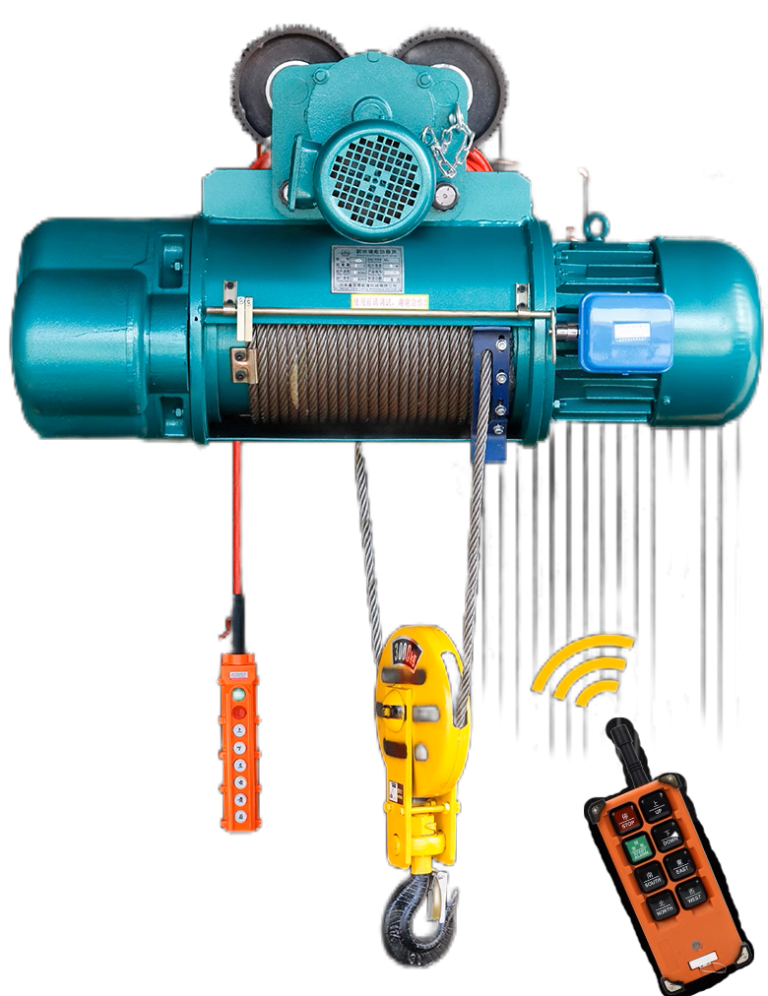

Moreover, the operational efficiency of LX electric suspension cranes is significantly enhanced by their electric drive systems. These systems provide smooth and precise control over lifting and lowering operations, which is crucial in environments where accuracy is paramount. The electric motors used in these cranes are designed to deliver consistent power, reducing the risk of mechanical failure and minimizing downtime. Consequently, industries that rely on continuous production can benefit from the reliability and performance of LX electric suspension cranes, ensuring that operations remain uninterrupted.

In addition to their efficiency, LX electric suspension cranes are also recognized for their safety features. The design incorporates advanced safety mechanisms, such as overload protection and emergency stop functions, which are essential in preventing accidents and ensuring the well-being of operators and personnel in the vicinity. Furthermore, the cranes are equipped with user-friendly controls that allow operators to maneuver loads with precision, reducing the likelihood of mishaps during lifting operations. This focus on safety not only protects workers but also safeguards valuable equipment and materials, ultimately contributing to a more secure working environment.

Another significant advantage of LX electric suspension cranes is their adaptability to various industrial settings. These cranes can be customized to meet the specific needs of different applications, whether in manufacturing, warehousing, or construction. The flexibility in design allows for modifications in lifting capacity, span length, and operational speed, making them suitable for a wide range of tasks. This adaptability ensures that businesses can invest in a crane system that aligns with their operational requirements, thereby enhancing productivity and reducing the need for multiple lifting solutions.

Furthermore, the maintenance of LX electric suspension cranes is relatively straightforward, which is a crucial factor for industries aiming to minimize operational costs. The electric components are designed for durability and require less frequent servicing compared to their hydraulic counterparts. This reduced maintenance requirement not only lowers the overall cost of ownership but also allows maintenance personnel to focus on other critical areas of the operation, thereby improving overall efficiency.

In conclusion, LX electric suspension cranes offer a comprehensive array of advantages that make them an ideal choice for various industrial applications. Their ability to optimize space, enhance operational efficiency, and prioritize safety positions them as a valuable asset in any industrial setting. Additionally, their adaptability and ease of maintenance further solidify their status as a preferred lifting solution. As industries continue to evolve and demand more efficient and reliable equipment, LX electric suspension cranes are poised to play a crucial role in meeting these challenges, ultimately driving productivity and safety in the workplace.

Key Features to Look for in Custom LX Electric Suspension Crane Manufacturers

When considering the procurement of an LX electric suspension crane, it is essential to identify key features that distinguish reputable custom manufacturers in this specialized field. The selection process begins with an understanding of the manufacturer\\u2019s experience and expertise in producing electric suspension cranes. A manufacturer with a proven track record in the industry is likely to possess the necessary knowledge and skills to deliver high-quality products tailored to specific operational needs. This experience often translates into a deeper understanding of the nuances involved in crane design, safety standards, and regulatory compliance.

Moreover, the customization capabilities of a manufacturer play a pivotal role in ensuring that the crane meets the unique requirements of various applications. A reliable manufacturer should offer a range of customization options, including load capacities, span lengths, and control systems. This flexibility allows businesses to optimize their operations by selecting a crane that aligns perfectly with their operational demands. Additionally, the ability to customize features such as hoisting mechanisms and safety devices can significantly enhance the crane’s functionality and reliability.

In addition to customization, the quality of materials used in the construction of the crane is another critical factor to consider. High-quality materials not only contribute to the durability and longevity of the crane but also ensure that it can withstand the rigors of daily use in demanding environments. Manufacturers that prioritize the use of premium materials, such as high-strength steel and corrosion-resistant components, are more likely to produce cranes that require less maintenance and have a longer service life. Consequently, this focus on quality can lead to reduced operational costs over time.

| No. | Commodity Name |

| 1 | LDY metallurgical electric single beam crane |

| 2 | Rubber – tired Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Furthermore, it is essential to evaluate the technological advancements incorporated into the crane’s design. Modern LX electric suspension cranes should feature state-of-the-art technology that enhances performance, safety, and ease of use. For instance, advanced control systems, such as programmable logic controllers (PLCs) and remote operation capabilities, can significantly improve operational efficiency. Additionally, features like overload protection and automatic shut-off mechanisms are vital for ensuring the safety of both operators and the surrounding environment. Manufacturers that invest in innovative technology demonstrate a commitment to providing cutting-edge solutions that meet the evolving needs of their clients.

Another important aspect to consider is the level of customer support and service offered by the manufacturer. A reputable manufacturer should provide comprehensive support throughout the entire lifecycle of the crane, from initial consultation and design to installation, maintenance, and after-sales service. This ongoing support is crucial for addressing any issues that may arise and ensuring that the crane operates at peak performance. Manufacturers that offer training programs for operators and maintenance personnel further enhance the value of their products by ensuring that users are well-equipped to handle the equipment safely and effectively.

Lastly, it is advisable to review customer testimonials and case studies to gauge the manufacturer\\u2019s reputation in the industry. Feedback from previous clients can provide valuable insights into the quality of the products and services offered, as well as the manufacturer\\ufffd\\ufffds responsiveness to customer needs. By considering these key features\\u2014experience, customization capabilities, material quality, technological advancements, customer support, and reputation\\u2014businesses can make informed decisions when selecting a custom LX electric suspension crane manufacturer, ultimately leading to enhanced operational efficiency and safety in their operations.