Table of Contents

रेल प्रकार कन्टेनर ग्यान्ट्री क्रेनका फाइदाहरू

रेल प्रकार कन्टेनर ग्यान्ट्री क्रेनका विशेषताहरू

Nr.

लेखको नाम

QZ ओभरहेड क्रेन GRAB CAP.5-20T सँग

| विश्वव्यापी गैन्ट्री क्रेन | युरोपेली शैली क्रेन |

| 1 | हार्बर क्रेन |

| 2 | रेल प्रकार कन्टेनर ग्यान्ट्री क्रेनको लागि मर्मत सुझावहरू |

| 3 | रेल प्रकारको कन्टेनर ग्यान्ट्री क्रेनहरू ढुवानी उद्योगमा आवश्यक उपकरणहरू हुन्, कन्टेनरहरूलाई जहाजबाट भण्डारण यार्डहरूमा कुशलतापूर्वक सार्नको लागि प्रयोग गरिन्छ। यी क्रेनहरू भारी भारहरू ह्यान्डल गर्न र माग गरिएको वातावरणमा सञ्चालन गर्न डिजाइन गरिएको हो। रेल प्रकारको कन्टेनर ग्यान्ट्री क्रेनहरूको सहज सञ्चालन सुनिश्चित गर्न, नियमित मर्मत महत्त्वपूर्ण छ। यस लेखमा, हामी रेल प्रकारको कन्टेनर ग्यान्ट्री क्रेनहरूलाई इष्टतम कामको अवस्थामा राख्न मद्दत गर्नका लागि केही मर्मत सुझावहरू छलफल गर्नेछौं। ढिलो बोल्टहरू वा क्षतिग्रस्त कम्पोनेन्टहरू जस्ता लुकेको र आँसुको कुनै पनि संकेतहरूको लागि क्रेनको निरीक्षणले दुर्घटनाहरू र डाउनटाइम रोक्न मद्दत गर्न सक्छ। प्रत्येक शिफ्ट अघि क्रेनको दैनिक दृश्य निरीक्षण गर्न सिफारिस गरिन्छ, साथै साप्ताहिक वा मासिक आधारमा थप गहन निरीक्षणहरू। घर्षण र पहिरन रोक्नको लागि गतिशील भागहरूको उचित स्नेहन आवश्यक छ, जसले ब्रेकडाउन र महँगो मर्मत गर्न सक्छ। क्रेनको प्रत्येक भागको लागि सही प्रकारको स्नेहक प्रयोग गर्न र स्नेहन अन्तरालहरूको लागि निर्माताको सिफारिसहरू पालना गर्न महत्त्वपूर्ण छ। धूलो, फोहोर र मलबे क्रेनको कम्पोनेन्टहरूमा जम्मा हुन सक्छ र यसको सञ्चालनमा हस्तक्षेप गर्न सक्छ। हल्का डिटर्जेन्ट र पानीको साथ नियमित सफाईले क्रेनको निर्माणलाई रोक्न र लामो समयसम्म मद्दत गर्न सक्छ। बिजुलीका कम्पोनेन्टहरू जस्तै केबलहरू, कनेक्टरहरू, र नियन्त्रण प्यानलहरू क्षति वा लुगाको संकेतहरूको लागि निरीक्षण गरिनुपर्छ। खराबी रोक्न र क्रेन अपरेटरहरूको सुरक्षा सुनिश्चित गर्न विद्युतीय प्रणालीको कुनै पनि समस्यालाई तुरुन्तै सम्बोधन गर्न महत्त्वपूर्ण छ। अपरेटरहरूलाई कसरी सुरक्षित र प्रभावकारी रूपमा क्रेन सञ्चालन गर्ने, साथै कुनै पनि मर्मतसम्भार समस्याहरू कसरी पहिचान गर्ने र रिपोर्ट गर्ने भनेर तालिम दिइनुपर्छ। नियमित प्रशिक्षण सत्रहरूले यो सुनिश्चित गर्न मद्दत गर्न सक्छ कि अपरेटरहरू उत्तम अभ्यासहरू र सुरक्षा प्रक्रियाहरूमा अद्यावधिक छन्। यी मर्मत सुझावहरू पछ्याएर, क्रेन अपरेटरहरूले दुर्घटनाहरू रोक्न, डाउनटाइम कम गर्न, र उपकरणको जीवन लम्ब्याउन मद्दत गर्न सक्छन्। नियमित निरीक्षण, स्नेहन, सफाई, विद्युत प्रणाली जाँच, र अपरेटर प्रशिक्षण रेल प्रकार कन्टेनर ग्यान्ट्री क्रेन को लागी एक व्यापक मर्मत कार्यक्रम को सबै आवश्यक घटकहरु हुन्। मर्मतसम्भारमा समय र स्रोतहरू लगानी गरेर, कम्पनीहरूले उनीहरूका क्रेनहरू सुरक्षित र कुशलतापूर्वक सञ्चालन गर्छन्, उनीहरूको सञ्चालनको सफलतामा योगदान पुर्याउन सक्छन्। |

| 4 | Harbour crane |

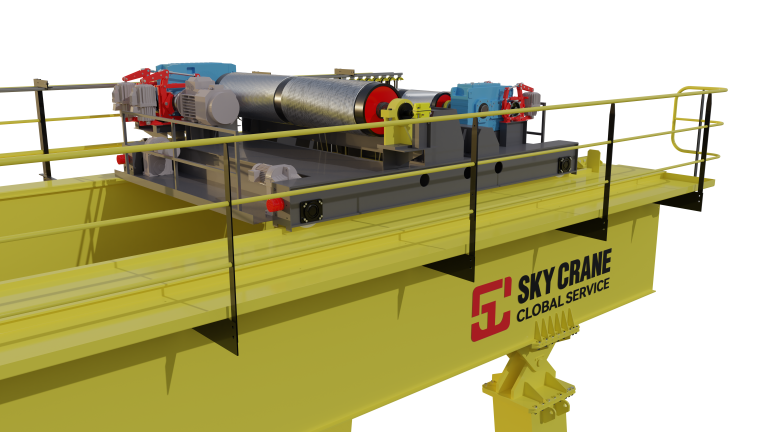

Another notable feature of rail type container gantry cranes from China’s best makers is their high lifting capacity. These cranes are capable of lifting heavy containers with ease, making them ideal for handling large volumes of cargo. The lifting mechanisms of these cranes are designed to provide smooth and reliable operation, ensuring that containers are moved quickly and safely.

Furthermore, rail type container gantry cranes from China’s best makers are designed for versatility. These cranes can be customized to meet the specific requirements of different applications, whether it be in a port, terminal, or storage yard. They can be equipped with various attachments and accessories to enhance their functionality and efficiency.

Safety is also a top priority for rail type container gantry cranes from China’s best makers. These cranes are equipped with a range of safety features, including overload protection systems, emergency stop buttons, and anti-collision devices. These safety features help to prevent accidents and ensure the well-being of operators and workers.

In conclusion, rail type container gantry cranes from China’s best makers are characterized by their robust construction, advanced technology, high lifting capacity, versatility, and safety features. These cranes are designed to meet the demands of the shipping and logistics industry and provide reliable and efficient operation. With their exceptional performance and quality, rail type container gantry cranes from China’s best makers are a top choice for businesses looking to enhance their container handling operations.

Maintenance Tips for Rail Type Container Gantry Crane

Rail type container gantry cranes are essential equipment in the shipping industry, used for efficiently moving containers from ships to storage yards. These cranes are designed to handle heavy loads and operate in demanding environments. To ensure the smooth operation of rail type container gantry cranes, regular maintenance is crucial. In this article, we will discuss some maintenance tips for rail type container gantry cranes to help keep them in optimal working condition.

One of the most important maintenance tasks for rail type container gantry cranes is regular inspection. Inspecting the crane for any signs of wear and tear, such as loose bolts or damaged components, can help prevent accidents and downtime. It is recommended to perform daily visual inspections of the crane before each shift, as well as more thorough inspections on a weekly or monthly basis.

Another key aspect of maintenance for rail type container gantry cranes is lubrication. Proper lubrication of moving parts is essential to prevent friction and wear, which can lead to breakdowns and costly repairs. It is important to use the correct type of lubricant for each component of the crane and to follow the manufacturer’s recommendations for lubrication intervals.

In addition to regular inspections and lubrication, it is important to keep the rail type container gantry crane clean. Dust, dirt, and debris can accumulate on the crane’s components and interfere with its operation. Regular cleaning with a mild detergent and water can help prevent buildup and prolong the life of the crane.

Another maintenance tip for rail type container gantry cranes is to check the electrical system regularly. Electrical components such as cables, connectors, and control panels should be inspected for signs of damage or wear. It is important to address any issues with the electrical system promptly to prevent malfunctions and ensure the safety of the crane operators.

Proper training of crane operators is also essential for the maintenance of rail type container gantry cranes. Operators should be trained on how to operate the crane safely and efficiently, as well as how to identify and report any maintenance issues. Regular training sessions can help ensure that operators are up to date on best practices and safety procedures.

In conclusion, maintenance is a critical aspect of keeping rail type container gantry cranes in optimal working condition. By following these maintenance tips, crane operators can help prevent accidents, reduce downtime, and prolong the life of the equipment. Regular inspections, lubrication, cleaning, electrical system checks, and operator training are all essential components of a comprehensive maintenance program for rail type container gantry cranes. By investing time and resources in maintenance, companies can ensure that their cranes operate safely and efficiently, contributing to the success of their operations.