Table of Contents

Advantages of Using Single-Beam Bridge Crane in Industrial Settings

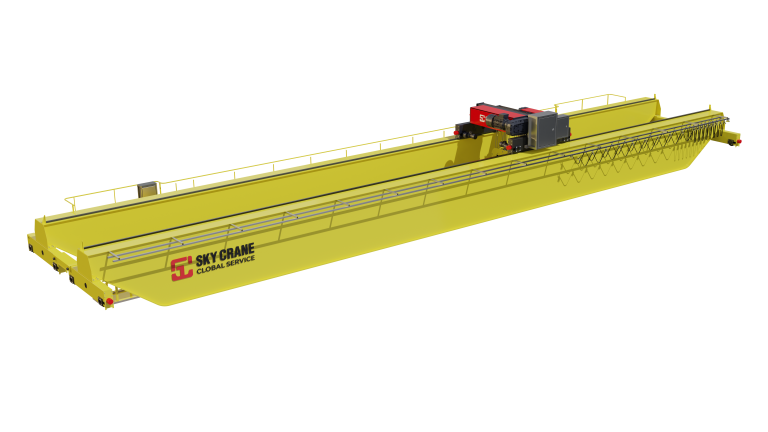

Single-beam bridge cranes are a popular choice in industrial settings due to their numerous advantages. These cranes are designed to efficiently lift and move heavy loads within a facility, making them essential for various industries such as manufacturing, construction, and warehousing. In this article, we will explore the benefits of using single-beam bridge cranes in industrial settings.

One of the main advantages of single-beam bridge cranes is their cost-effectiveness. These cranes are typically more affordable than double-beam bridge cranes, making them a practical choice for businesses looking to maximize their budget. Despite their lower cost, single-beam bridge cranes are still capable of handling heavy loads with ease, making them a cost-effective solution for many industrial applications.

Another advantage of single-beam bridge cranes is their versatility. These cranes can be customized to meet the specific needs of a facility, whether it be in terms of load capacity, span length, or lifting height. This flexibility allows businesses to tailor their crane system to suit their unique requirements, ensuring optimal performance and efficiency.

Single-beam bridge cranes are also known for their ease of installation and maintenance. These cranes are typically lighter and more compact than double-beam bridge cranes, making them easier to install and maneuver within a facility. Additionally, single-beam bridge cranes require less maintenance compared to their double-beam counterparts, resulting in lower downtime and reduced maintenance costs for businesses.

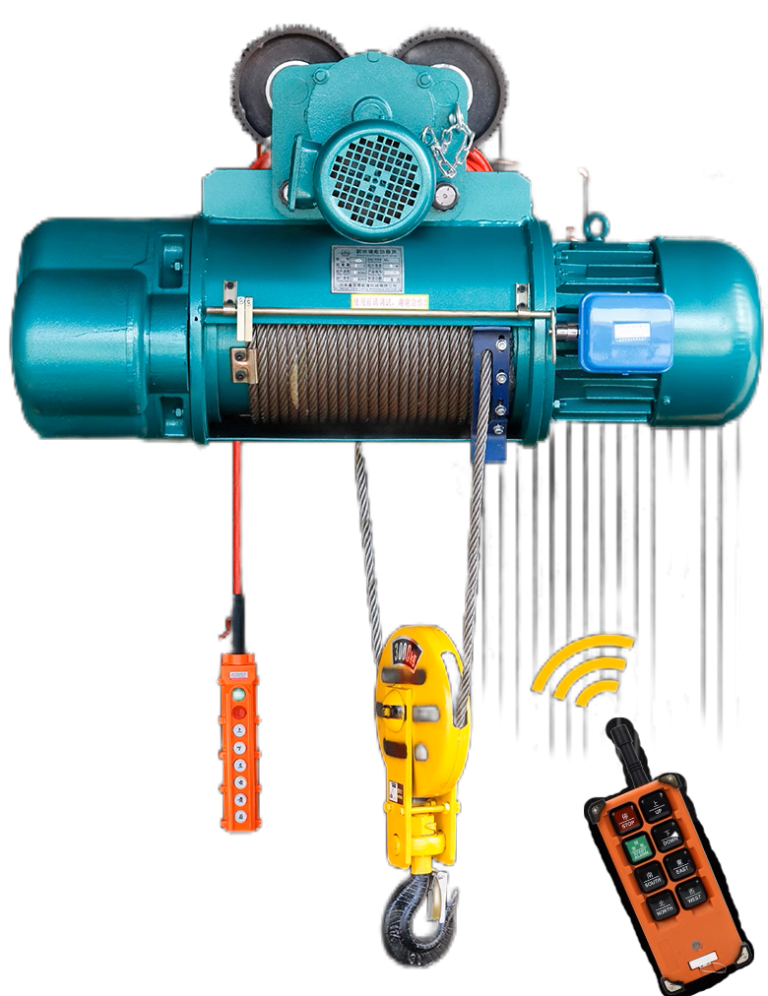

In terms of safety, single-beam bridge cranes offer several advantages. These cranes are equipped with various safety features such as overload protection, emergency stop buttons, and limit switches to ensure the safe operation of the crane. Additionally, single-beam bridge cranes can be operated remotely, allowing operators to control the crane from a safe distance, further enhancing workplace safety.

Single-beam bridge cranes are also known for their efficiency and productivity. These cranes are designed to lift and move heavy loads quickly and efficiently, reducing downtime and increasing productivity in industrial settings. With their high lifting capacity and fast lifting speeds, single-beam bridge cranes can help businesses streamline their operations and improve overall efficiency.

Furthermore, single-beam bridge cranes are highly durable and reliable. These cranes are built to withstand the rigors of daily use in industrial environments, ensuring long-lasting performance and minimal downtime. With proper maintenance and care, single-beam bridge cranes can provide years of reliable service, making them a valuable investment for businesses.

In conclusion, single-beam bridge cranes offer numerous advantages for businesses operating in industrial settings. From cost-effectiveness and versatility to safety and efficiency, these cranes are an essential tool for lifting and moving heavy loads within a facility. With their ease of installation and maintenance, as well as their durability and reliability, single-beam bridge cranes are a practical and efficient solution for businesses looking to optimize their operations and maximize productivity.

Safety Measures and Maintenance Tips for Single-Beam Bridge Crane Operations

Single-beam bridge cranes are a common type of overhead crane used in various industries for lifting and moving heavy loads. While these cranes are efficient and versatile, it is important to prioritize safety measures and proper maintenance to ensure smooth and safe operations.

One of the key safety measures for single-beam bridge crane operations is proper training for crane operators. Operators should be trained on how to safely operate the crane, including how to properly inspect the crane before use, how to safely lift and move loads, and how to respond to emergencies. Regular training and refresher courses can help ensure that operators are up-to-date on best practices and safety protocols.

In addition to training, it is important to establish clear safety procedures and guidelines for single-beam bridge crane operations. This includes establishing load limits, proper lifting techniques, and safe operating speeds. Operators should also be aware of potential hazards in the work environment, such as overhead obstructions, power lines, or other equipment that could interfere with crane operations.

Regular inspections and maintenance are also crucial for ensuring the safe operation of single-beam bridge cranes. Inspections should be conducted before each use to check for any signs of wear or damage, such as worn cables, loose bolts, or damaged electrical components. Any issues should be addressed promptly to prevent accidents or equipment failures.

Proper maintenance of single-beam bridge cranes includes regular lubrication of moving parts, checking for proper alignment of the crane rails, and inspecting electrical components for signs of wear or damage. Regular maintenance can help prevent breakdowns and extend the lifespan of the crane.

| Number | Commodity Name |

| 1 | LX electric suspension crane |

| 2 | L-type gantry crane |

| 3 | European-style crane |

| 4 | Harbour crane |

It is also important to keep the work area around the crane clear of obstructions and debris. This includes ensuring that there is enough clearance for the crane to move freely and that there are no obstacles that could interfere with the operation of the crane. Operators should also be aware of their surroundings and communicate with other workers in the area to prevent accidents.

When operating a single-beam bridge crane, it is important to follow proper lifting techniques to ensure the safety of both the operator and the load being lifted. This includes using the appropriate lifting attachments, securing the load properly, and avoiding sudden movements or jerks that could cause the load to swing or fall.

In the event of an emergency or equipment failure, operators should be trained on how to respond quickly and effectively. This includes knowing how to safely lower a load in the event of a power failure, how to safely exit the crane in an emergency, and how to communicate with other workers in the area to ensure their safety.

By following these safety measures and maintenance tips, operators can help ensure the safe and efficient operation of single-beam bridge cranes. Prioritizing safety and proper maintenance can help prevent accidents, injuries, and equipment failures, ultimately leading to a safer work environment for everyone involved.